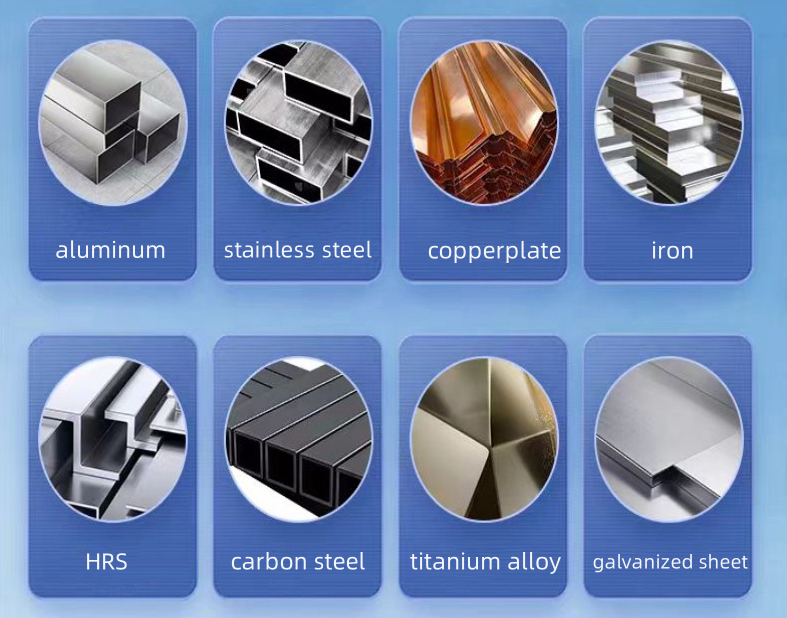

1. Bakin karfe

Bakin karfe yana da babban coefficient na thermal faɗaɗa, kuma yana da wuyar yin zafi yayin walda. Lokacin da yankin da zafi ya shafa ya yi girma kaɗan, zai haifar da matsalolin nakasa mai tsanani. Duk da haka, zafin da na'urar waldawa ta Laser na hannu ke haifar yayin duk aikin walda yana da ƙasa. Haɗe tare da ƙarancin ƙarancin thermal conductivity, babban ƙarfin sha mai ƙarfi da ƙarfin narkewa na bakin karfe, ingantaccen tsari, santsi da kyawawan welds ana iya samun su bayan waldawa.

2. Karfe Karfe

Ana iya walda karfen carbon na yau da kullun ta hanyar hannun hannuFiber Laser walda Machine, Tasirin ya yi kama da waldi na bakin karfe, kuma yankin da zafi ya shafa ya fi ƙanƙanta, amma lokacin walda matsakaici da babban ƙarfe na carbon, ragowar zafin jiki yana da girma, don haka har yanzu wajibi ne don waldawa kafin waldawa. Preheating da adana zafi bayan walda don kawar da damuwa da guje wa fasa. Anan zamu iya magana game da injin walda mai sanyi. Matsakaici da babban ƙarfe na carbon za a iya waldawa ko gyara shi cikin sauri a hankali tare da walda mai sanyi da simintin walda na ƙarfe. Dangane da yanayin kula da zafin jiki, kula da zafin jiki, da kula da zafin jiki, injin walda mai sanyi na iya koyar da waldawar laser ta hannu mafi inganci akan ragowar zafi bayan walda.

3. Mutuwar karfe

Ya dace da walda nau'ikan nau'ikan mutuƙar ƙarfe, kuma tasirin walda yana da kyau sosai.

4. Aluminum da aluminum gami

Aluminum da aluminum alloys kayan aiki ne masu nuni sosai, kuma porosity na iya bayyana a cikin narkakken tafkin ko a tushen lokacin walda. Idan aka kwatanta da kayan ƙarfe na baya, aluminum da aluminum alloys suna da buƙatu mafi girma don sigogi, amma idan dai zaɓaɓɓen sigogi na walda sun dace, za'a iya samun suturar weld tare da kayan aikin injiniya iri ɗaya kamar karfe tushe.

5. Copper da jan karfe gami

The thermal conductivity na jan karfe yana da ƙarfi sosai, kuma yana da sauƙi don haifar da shigar da bai cika ba da juzu'i na ɓangarori yayin walda. Yawancin lokaci, kayan jan ƙarfe yana zafi yayin aikin walda don taimakawa walda. A nan muna magana ne game da bakin ciki kayan jan karfe.Injin walƙiya Laser na hannuiya walda kai tsaye, saboda yawan kuzarinsa da saurin waldawar sa, ba shi da tasiri sosai daga babban zafin wutar lantarki na jan karfe.

6. Welding tsakanin dissimilar kayan

Na'urar waldawa ta hannu ta hannu za a iya aiwatar da ita tsakanin nau'ikan nau'ikan karafa iri-iri, kamar jan ƙarfe-nickel, nickel-titanium, jan ƙarfe-titanium, titanium-molybdenum, tagulla-jan karfe, ƙaramin ƙarfe-karfe-karfe na carbon da sauran nau'ikan karafa iri-iri. Ana iya yin waldawar Laser a kowane yanayi (gas ko zazzabi).

Na'urar waldawa ta Laser na hannuA halin yanzu samfur ne da ake amfani da shi sosai a masana'antar walda, musamman saboda duk da cewa wannan kayan aikin ya fi tsada, yana iya ceton kuɗin aiki sosai. Kudin aiki na walda yana da tsada sosai. Amfani da wannan Samfurin yana magance matsalar ɗaukar nauyi da wahala na masu walda. Bugu da ƙari, injin walƙiya na laser na hannu ya sami yabo baki ɗaya daga dubban abokan ciniki saboda tsawon rayuwar sabis da ƙarancin kuzari.

Idan kuna son ƙarin koyo game da tsaftacewar Laser, ko kuna son siyan injin tsabtace Laser mafi kyau a gare ku, da fatan za a bar saƙo a gidan yanar gizon mu kuma ku yi mana imel kai tsaye!

Lokacin aikawa: Dec-25-2024